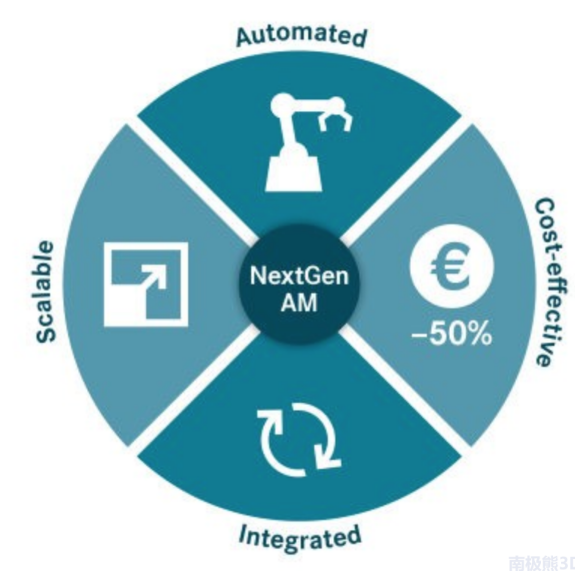

On May 7, 2019, the author learned from foreign media that the NextGenam project, which began to demonstrate the automated 3D printing production line in 2017, has completed the pilot phase. Nextgenam is a joint project between Premium Aerotec, EOS and Daimler to develop a digital additive manufacturing plant that can cost-effectively produce parts for the automotive and aerospace sectors. It is estimated that their production line will reduce manufacturing costs by 50% compared to other 3D printing systems.

Fully automated metal 3D printing production plant has been commissioned for 2 years, manufacturing cost reduced by 50%

Premium Aerotec Executive Chairman Dr. Thomas Emme said: "In the aircraft industry, Premium Aerotec is now an international pioneer in the field of metal 3D printing. The goal now is to further develop this expertise and make it It also works in other areas, so Nextgenam's success is another important component of our strategy."

Fully automated metal 3D printing production plant has been commissioned for 2 years, manufacturing cost reduced by 50%

Premium Aerotec is the first component manufacturer to offer 3D printed titanium parts for Airbus aircraft, so they are responsible for the management of the production process. EOS supplied all the equipment and software for the project; aluminum alloy (AlSi10mg) was used in most tests and production, and its strength and finish have improved significantly over the past two years.

Fully automated metal 3D printing production plant has been commissioned for 2 years, manufacturing cost reduced by 50%

The entire production line is automated. From data preparation to separation from the final components of the build platform, no manual operations are required and the build platform is cut by a robotic saw. All metal powder handling, printing, heat treatment and quality assurance are fully automated, equipped with robotics and driverless transport systems. The entire production line runs through a control station.

Dr. Adrian Keppler, CEO of EOS, said: “We are very proud of our achievements with Premium Aerotec and Daimler. The Nextgenam project is how industrial 3D printing is part of an automated process chain and is economical in mass production. Efficient use provides a very specific demonstration. Combined with the digital possibilities used here, the pilot plant represents a milestone in the digital manufacturing process."

Fully automated metal 3D printing production plant has been commissioned for 2 years, manufacturing cost reduced by 50%

After extensive testing by Daimler, the process and parts have passed the industry standard qualification review, and the production of series parts has begun. An example is an aluminum bracket for a diesel truck engine. Daimler Bus's 3D Printing Competence Center is currently evaluating the first 3D printed aluminum replacement parts for passenger cars and plans to produce parts for gas-powered and electric vehicles.

Jasmin Eichler, Head of Future Technology at Daimler AG, explains the desire to introduce AM into the automotive industry: “Additive manufacturing is also suitable for the smallest series of new cars (limited edition). System development for 3D printed parts means production Costs can be further reduced and quality optimized. In the advanced development of automobiles, 3D printing also has special significance. Compared with traditional production processes, it is usually more cost-effective to use the additive to produce low-volume products. And the production speed is faster."

Capacity will be further improved

The continuous 3D data link with integrated quality management makes this production system one of the first examples of future Industry 4.0 benchmarks. The manufacturing process is fully scalable: production lines can be easily replicated to increase plant capacity. As this number rises, it is expected that further savings will be made in the future. Today, pilot equipment has been able to automate the production of components and meet the quality standards for mass production.

The parts required by Daimler have been manufactured by Premium AEROTEC's new technology line. For example, the truck department has used the truck diesel engine brackets produced by Premium AEROTEC as the first replacement parts.

Replacement parts for trucks and buses

The 3D printing process is very useful in the field of replacement parts. Because of the problem with the tool or for some infrequently used replacement parts, 3D printing can result in lower part production costs and higher efficiency than traditional sand or die casting processes. Currently, the 3D Printing Competence Center of Daimler Bus is reviewing the print request for the first 3D printed aluminum passenger car replacement parts. The analysis team in the passenger car sector is currently considering potential application possibilities for this technology.

Small parts mass production and opportunities for development

“Additive manufacturing is also suitable for the minimum mass production of new cars (limited editions). The systematic development of 3D printing-specific components means that production costs can be further reduced and quality can be continuously optimized.” Daimler's future technology is responsible According to Jasmin Eichler, “3D printing has a special meaning in the development of automotive technology. Compared with traditional production processes, additive manufacturing can usually produce the required number of products more economically and quickly.”

3D printing is also suitable for internal combustion engine vehicles and electric vehicles, such as cooling circuit integrated substrates in which electric batteries are installed in electric vehicles.

High product quality

The pilot plant is based on high product quality: the aerospace and aerospace sectors also require the use of high-strength aluminum/magnesium/niobium alloys (also known as Scalmalloy).

The classic material often used in the automotive industry is aluminum alloy (AlSi10Mg), and its performance is constantly improving in pilot projects. Material strength and finished quality have improved significantly compared to the beginning of the cooperation two years ago.

Premium AEROTEC is the world's first component manufacturer to supply titanium 3D printed parts for Airbus aircraft production. The company is a global leader in aviation and its core business is the development and manufacture of aircraft structures made of metal and carbon fiber composites. The company has plants in Augsburg, Bremen, Nordenham and Farrell, Germany. Premium AEROTEC is responsible for the entire production process in the joint project.

EOS is a global technology leader in 3D printing for the metal and polymer materials industry. Founded in 1989, EOS is an independently operated company that provides a comprehensive additive manufacturing solution as a pioneer and innovator. EOS' portfolio of solutions including systems, materials and process parameters helps customers build a decisive competitive advantage in product quality, achieve sustainable production and achieve long-term economic benefits. In the joint project, EOS is responsible for providing all 3D printing technologies and related software solutions, as well as control centers for connecting and managing the production chain.

Daimler contributed to the project's experience in large-scale mass production. In this project, Daimler's research department works closely with the senior development department, which includes parts samples, algorithm robustness and digitization of component data throughout the production process. Testing of parts samples and manufacturing specifications standardized for 3D printing are also the responsibility of the car manufacturer. In addition, it is responsible for monitoring verification and certification according to the standards for mass production in VDA 6.3.

Copyright © 2017-2024 Nanjing Wiiking 3D Technology Co., Ltd. All rights reserved. Privacy & Security Policies